Cleaning - Washing

The first stage in the oil extraction process is cleaning the olives and segregating them from the leaves, stones, twigs, dirt etc. that are gathered along with the olives, thus, reducing the presence of any contaminants. Accordingly, the olives are inserted into a machine, where defoliation and the removal or any light item mixed with the fruit, are being achieved with the use of compressed air.

Thereupon, the olive fruits are being washed in special washers that are part of the machinery of the olive press. There, the fruit is being subjected to washing under the great force of running water which continuously rotates the olives, sending the heavier items at the bottom of the tank and the lighter ones on the surface from where they are being easily discharged.

Breaking and Milling

The second step after washing the olive fruits is crushing them into a paste. Hence, the olive kernels are being transferred through a worm gear (based on the spiral of Archimedes) to the grinder which contains a mechanical crusher. For an olive press, this is the most important processing stage of olive oil production.

Kneading (Malaxing) of the Olive Pulp

In order to separate the oil from the pulp obtained by milling the olives, the pulp should be first re-mixed in steel containers and thus, become more consistent, in order to allow maximum oil extraction. The kneader is a mixing machine where the olive paste is kneaded and homogenized. It is composed of a malaxing bath of U shape with double walls for the circulation of warm water which is constantly flowing for the adjustment of the temperature within the machine. In the interior of the kneader, there is a pair of rotors at both ends which continuously knead the olive paste.

The kneader might be horizontal. In this case, kneading’s duration reaches c. the 50 minutes. The temperature during kneading should not outreach the 27 ° C. The same applies to all processing stages of olive oil production. This is the reason why these processes are called “cold-bloodedly treatments”.

The olive paste should not come into contact with air, as this would cause the loss of a series of sensory components upon which the flavour and taste of the extracted oil greatly depend.

Horizontal Separator (Decanter)

When the processing stage of kneading is successfully completed, the next step consists in separating the oil from the rest of the olive components (various solid bodies and vegetable oils).

Nowadays, the separation of vegetable oils from the olive kernel is achieved with the use of centrifugal decanters whose function is based on gravitational separation (exploiting the difference in density, and thus, gravity of the various components of the olive paste). The newly developed generation of decanters integrates the operation of two separators into one centrifugal machine (two-phase centrifuge). The wet paste is inserted in the first centrifuge which separates the kernels from the vegetable oils and olive oil that are outpoured together. This liquid product is being further processed in specialised industrial units.

The greatest advantage of this new technology is that - the once unavoidable - exudation of sap which used to be discarded around the olive presses and contaminate the environment, is now eliminated. Therefore, it is definitely an eco-friendly technology.

For the final separation, the mixture of vegetable oils and olive oil that is coming out of the first centrifuge is further processed by a second centrifuge that rotates faster..

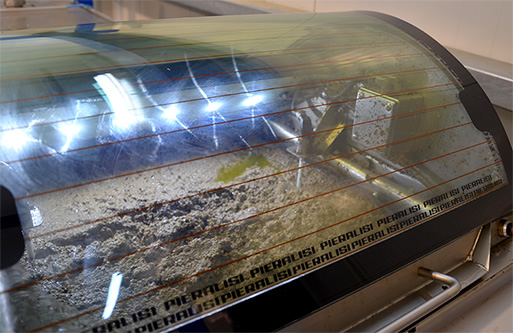

Second Centrifugal Separator

The liquid mixture that comes out of the first centrifuge is ready for the final and most critical processing stage; the stage of the final separation of the oil from the vegetable oils. A different type of centrifugal separator, along with special tubing, is used for this processing stage.

The liquid mixture continuously flows into the machine. The discs that are found in the interior of the machine and rotate around a vertical axis with the rotation speed reaching the 6.000 - 7.000 rpm, separate the oil from the rest of the liquids which unceasingly come out of the machine in different directions.